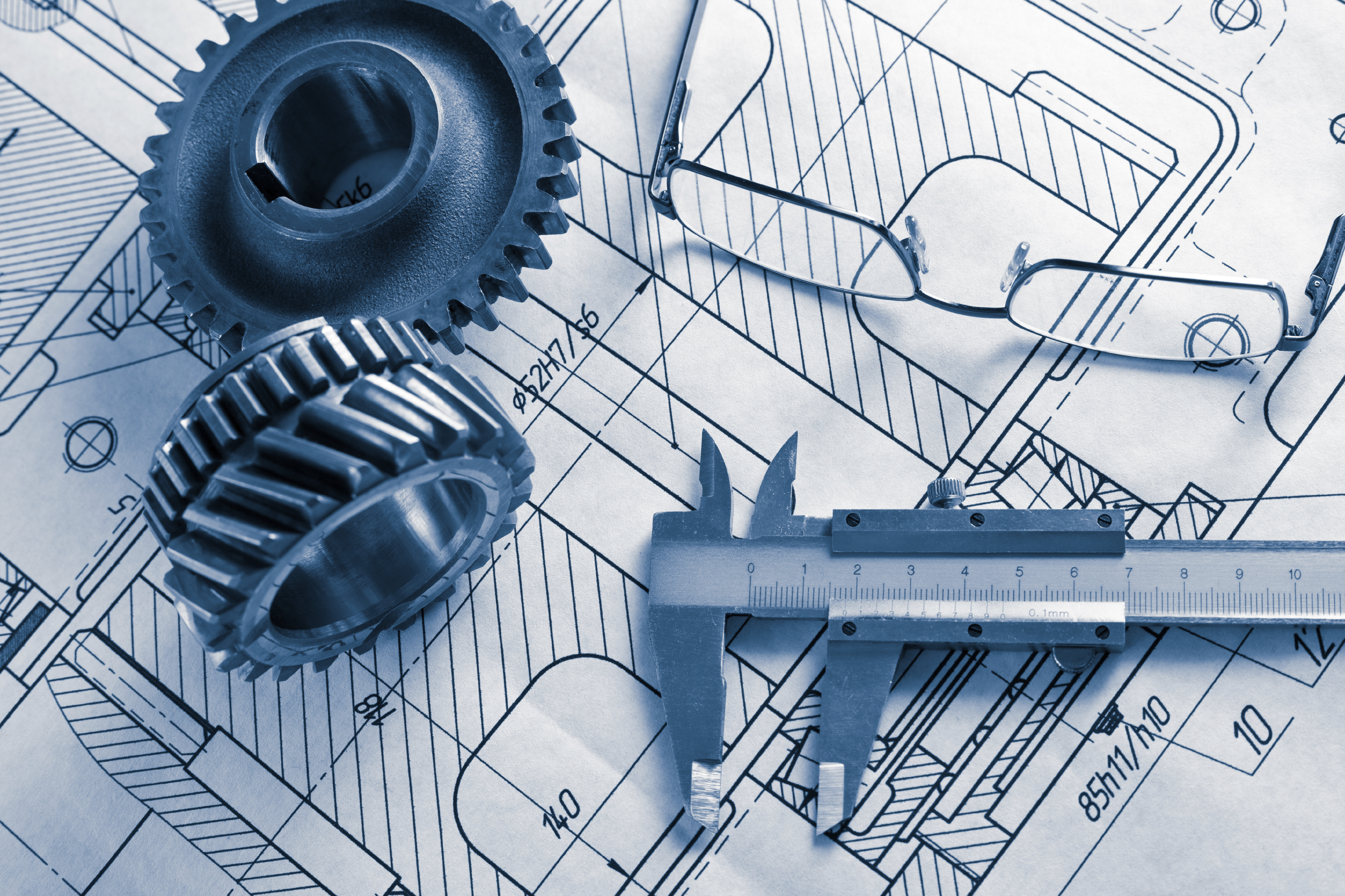

Sheet metal fabrication is the process of turning flat sheets of steel or aluminum into metal structures or products, by cutting, punching, folding and assembling. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. Typical forming tools are brakes, punches, and dies which can form angular bends and features. Sheet metal can be cut, bent or stretched into nearly any shape. Sheet metal parts are known for their durability, which makes them great for end-use applications. Parts used for low-volume prototypes and high-volume production runs are most cost-effective due to large initial setup and material costs.

Industries Served

Networking

Commercial

Gaming

Medical

Military

Industrial

Telecom

Automotive

Data Computers

Point of Purchase

EPC is proud to represent

HPM has been partnering with customers by providing expert design input to make Precision Sheet Metal parts and assemblies. We deliver quality items, on time, with your cost parameters taking priority. Our Account Management, Design Engineering, and Customer Service Support yield rapid prototyping, quick turn production, and customer service excellence.