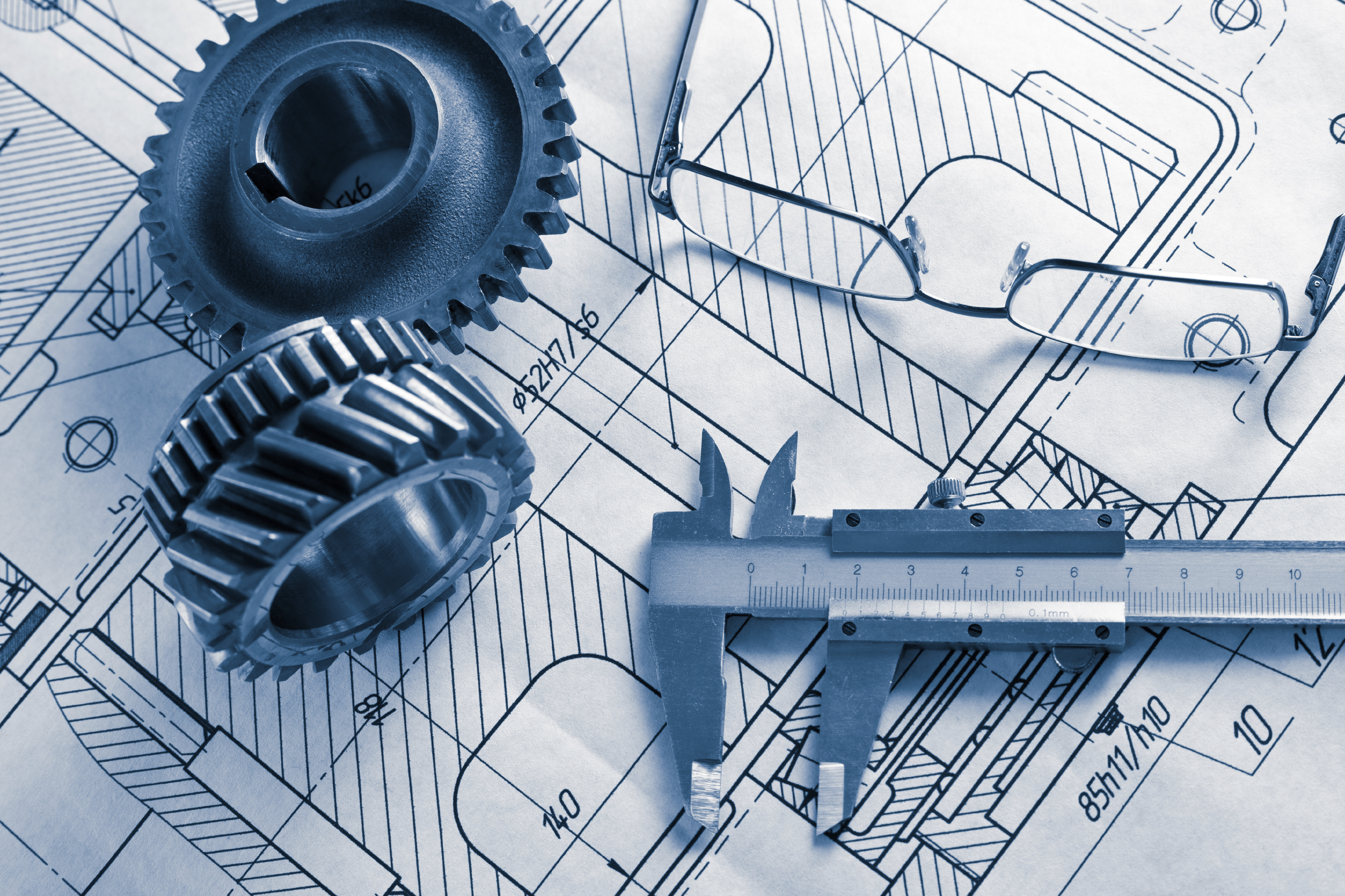

Metal Injection Molding (MIM) is a metalworking process in which fine powdered metal is mixed with binder material to create a “feedstock.” That is then shaped and solidified using an injection molding process. This molding process allows high volume, complex parts to be shaped in a single step. After molding, the part undergoes conditioning operations to remove the binder and densify the powders. MIM is a proven, innovative powder metallurgy technology that offers the capability of mass producing complex-shaped metal parts consistently and reliably.

Industries Served

Firearms

Defense

Medical

Dental

Computers

Aerospace

Automotive

Recreation

Appliance

EPC is proud to represent

SSI Sintered Specialties is a world leader in the production of complex, high volume production, and high-performance components through a technology portfolio which includes press and sinter powdered metallurgy (including high-densities), metal injection molding, and binder jet metal additive manufacturing technologies.